Costa Rica Leather Tannery 1977

Tracks of the StoneBear Copyright MCMLXIII Uncle Hargus ALL Rights reserved

ROF= Ring of fire Odyssey MEF-H = Marine Expeditionary Force- Hargus

Business in Costa Rica 1977

Leather Tannery , Davids chairs.

It was light enough to see walking around, dark and dim to take pix but I got a few on the old medieval side, the intake side of the tannery. This was a primitive factory/ processing plant/ business in Costa Rica.

Tico factory worker adjusting the rolling vat with raw leather hides inside, tumbling like a front load washing machine.

The processing vats in the floor were stone masonry tubs 3' deep x 6 to 7' square/circle. The whole place was stone masonry. I don't know if there was any paint left on the walls and not peeled/ eaten off the walls by the acrid chemicals in the processing vats.

Rocks placed on piles of soaking hides to keep submerged.

Walking around the different soaking vats challenged the sense of smell from the strange odors in different sections ranging from putrid bloody hides, to acrid, to alkaline.

After seeing the pile of raw, bloody cattle hides delivered from the carne/ beef slaughterhouse it was an all out assault on senses.

This tanneria worked on basic primitive chemical processing.

These are some wet salted tumbler vats, they operate like a front loading washing machine, then the tannery processes like an assembly line next dry salted, then into the floor vats for wet blue, lime, pickled, then hung on the air frame and dried.

Tico factory worker in the Guanacaste wood shop.

I don't know the amounts of chemicals that were used for basic salt/ brine/ alkalines, or acids but this process goes back thousands of years.

Tica lady factory worker.

Leather hides, some dyed, stacked for buyers to inspect and pick out. Center of pic is Steve Hough in dark shirt, Whit in jeans.

Leather hides hanging to air dry after going through an ironing/ flatening press.

Later we went to a factory near San Jose where they processed the leather hides for finished use in commercial products. As per customer orders they would die hides with colors ie... natural brown, red, blues, greens... any color. This leather would be bought for manufacturing shoes, boots, ladies purses, belts, briefcases, clothes bags, shoulder bags ect.

David Little measuring quality leather for chairs and several leather items.

This is a leather clothes hang up travel bag from Davids export company. After 35 years it is as good as the day I 1st traveled with it.

Years ago,... while riding on the airport shuttle bus... a stewardess said she would kill for this bag.

This is a leather clothes hang up travel bag from Davids export company. After 35 years it is as good as the day I 1st traveled with it.

Years ago,... while riding on the airport shuttle bus... a stewardess said she would kill for this bag.

Donna Little inspects shoe leather bases. Notice the shoulder strap leather purse?... Donna picked out the leather pieces and had these purses and other items manufactured.

This leather briefcase looks worn... maybe from the saddlesoap cleaning I gave it a decade ago... then rubbed it down with mink oil.... but it is still good.

This leather briefcase has made a LOT of sales calls!!!

This leather briefcase looks worn... maybe from the saddlesoap cleaning I gave it a decade ago... then rubbed it down with mink oil.... but it is still good.

This leather briefcase has made a LOT of sales calls!!!

Adjacent shoe manufacturing room.

David manufactured the most comfortable chair I've ever sat in. A wood frame lathed from Costa Rican Guanacaste wood,... a hardwood - also called Brasilian walnut. Enterolobium cyclocarpum commonly known as Guanacaste [wood]has a beautiful natural reddish brown color and made a really sturdy frame. The leather seats, seatbacks, and armrests were cut from the choice leather David picked out on the drying line... seen hanging from the overhead conveyor belt coming out of the dryers. Some chair leather was hand worked/ tooled by craftsmen with beautiful artistry. I saw some seats that were going to a western rancher that had a cattlemans/ ranch design tooled. These were absolutely beautiful chairs.

Guanacaste wood shop factory manufacturing

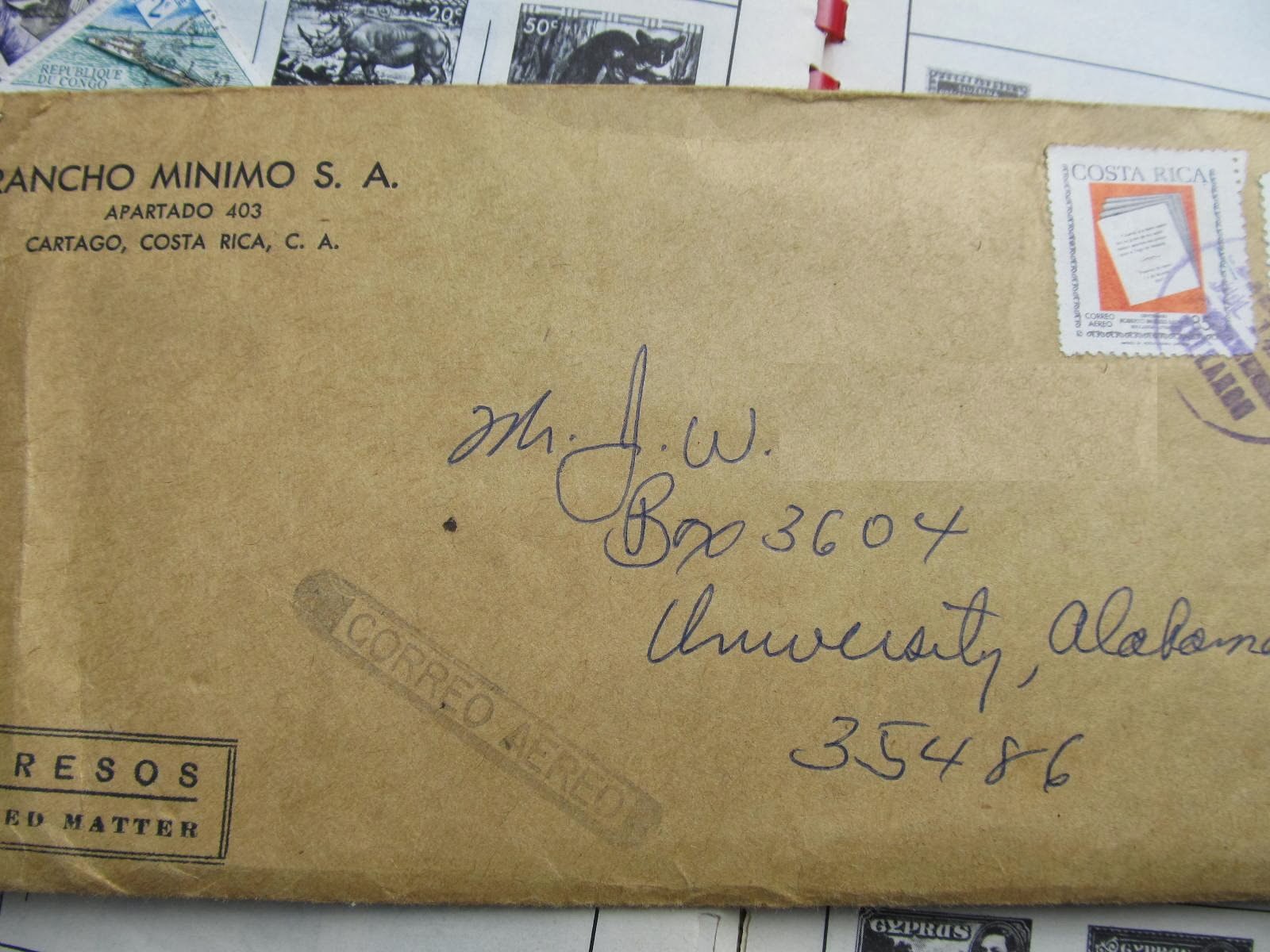

Davids company was Rancho Minimo = "Little Ranch" and I learned a LOT from David and Donna in a short time. David was a great mentor to me. We had that military / veterans bond. As an ex-Marine David treated me like his own Son. David was a retired Air Force Colonel that had been shot down over Korea and spent 2 years in a North Korean POW camp. He was a no bullshit guy. We saw eye to eye and got along great. They were mentors and I still miss them.

Studying in college and taking a summer journey to Costa Rica/ 3rd world Latin America was a wonderful experience to observe cultures, customs and the universality of markets and commerce; It changed my life!

You never drink twice from the same stream.

StoneBearTracks Copyright Uncle Hargus MCMLXIII ALL blog posts/photographs/video ALL Rights reserved

ALL Blog posts/photographs/video Copyright MCMLXIII ALL Rights Reserved